CILAM in Reunion Island

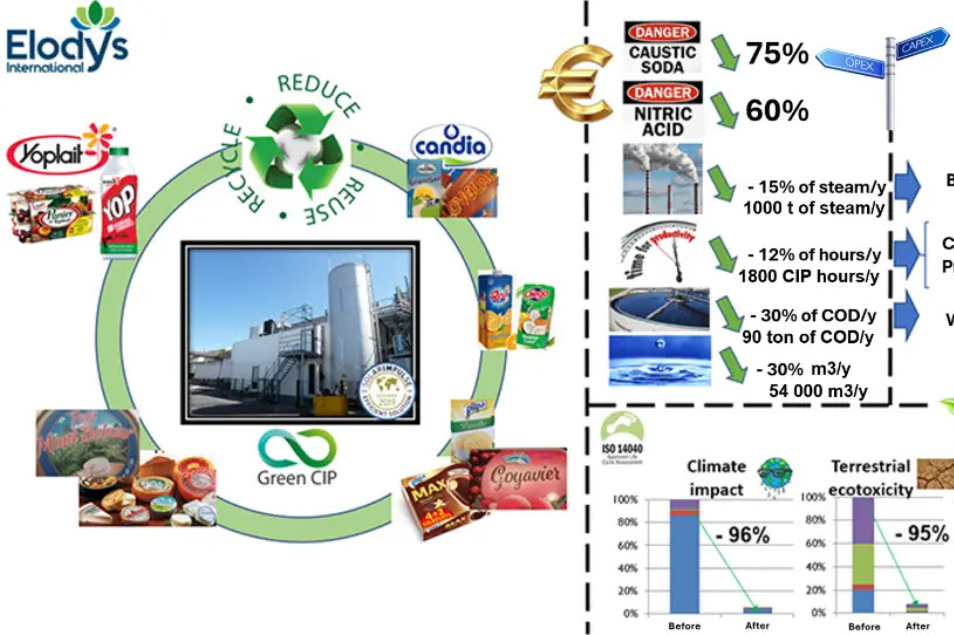

The first industrial installation was completed in 2012 at the CILAM site in Réunion. The GreenCIP has achieved significant savings and greatly reduced the environmental impact of the plant. We invite you to browse the articles posted by Mr. Olivier BARRAULT to recap the years of operation of this Green CIP unit:

"I am grateful to have led this innovative project with me that gives CILAM a head start in terms of CSR."